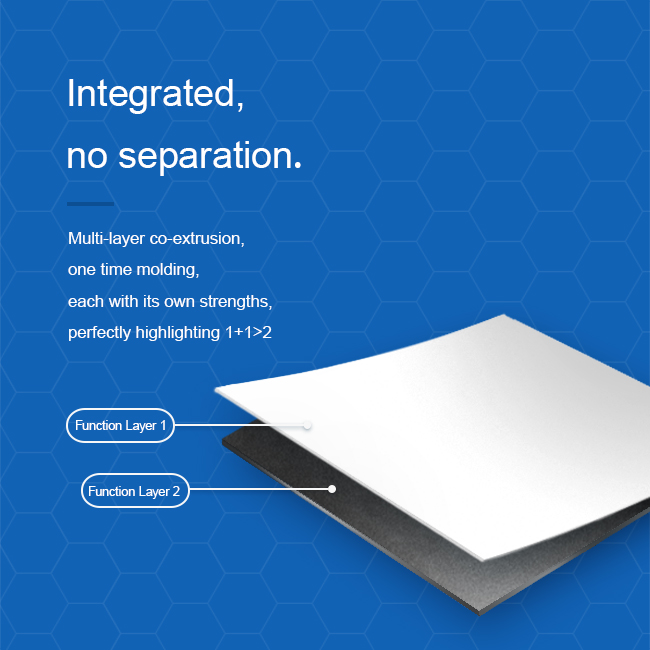

PC Multifunction Composite Plate

Product Parameters

|

Product Specification

Specification

|

|||||||||||

|

Property |

Test Method |

Unit |

Test data |

||||||||

| Tensile Strength |

ISO527 |

MPa |

38.2 |

||||||||

| Tear Trength |

ISO527 |

MPa |

27.2 | ||||||||

| Proportion |

ISO1183 |

g/cm3 |

1.2 |

||||||||

| UV Resistance |

UVA 315-400nm |

240H |

UVA Treated OK |

||||||||

|

High and low temperature test |

GB/T 2423.1-2001 |

100 cycles |

Qualified OK (-30℃-+80℃) |

||||||||

|

Vicat Softening Temperature |

ISO306 |

℃ |

142.6 |

||||||||

| Heat Distortion Temp |

ISO75 |

℃ |

107.1 |

||||||||

| Fire rating |

UL94 |

class |

V2 |

||||||||

| Reflectivity |

GB2410-80 |

% |

93.7 |

||||||||

| RoHS |

Directive 2011/65/EU (RoHs) |

— — |

Pass |

||||||||

| SVHC |

Regulation (EC) No 1907/2006 (REACH) |

— — |

Pass |

||||||||

| GWEPT |

IEC 60695-2-11:2021 |

℃ |

750 |

||||||||

|

|

|

|

|

||||||||

NOTE:

The above data are representative actual measurement data obtained through standard test methods, but not guaranteed values (the shipping standard values of key data are subject to internal tolerance or negotiated tolerance).

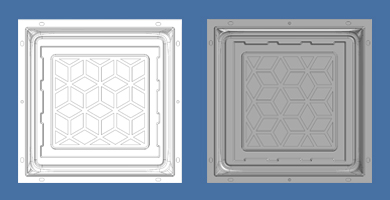

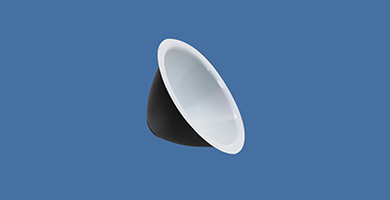

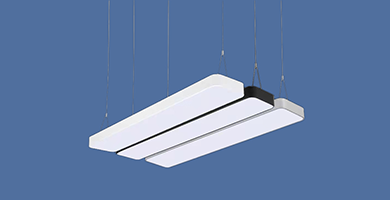

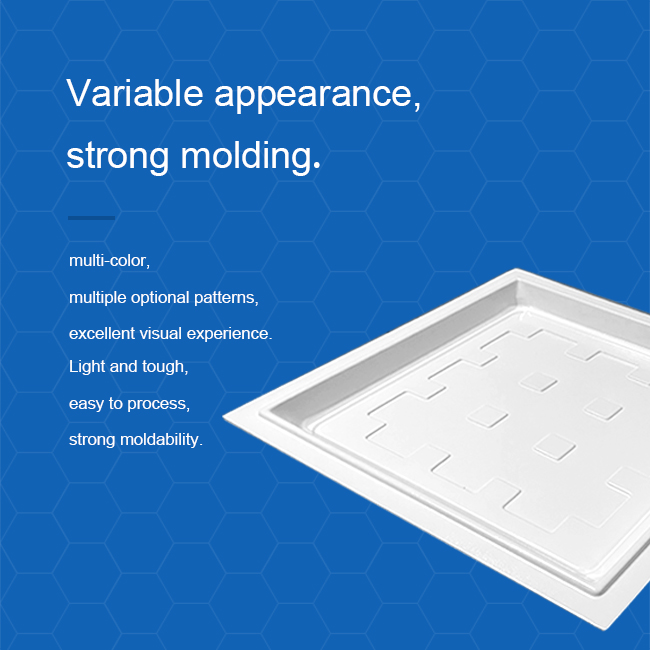

Product Utilization

Double layer or multi-layer materials are used for one-time composite molding .The product has light weight, high toughness, impact resistance, flame retardancy, weather resistance excellent processability. It adapts to a wide range of applications and support customized development.